Selecting the wrong type of transformer for an application can lead to inefficiency, safety hazards, and significant operational costs.

Where should we apply different types of transformers? This guide provides a detailed comparison of four essential transformer categories to powering our world.

1. Pad-Mounted Transformers: The Silent Sentinels of Urban Distribution

Ideal For: Underground distribution networks in dense urban centers, suburban neighborhoods, large commercial plazas, hospitals, and campuses where aesthetics and space are premium.Key Characteristics & Advantages:Enclosed Design: Housed in locked, tamper-resistant, and weatherproof steel cabinets, ensuring public safety and blending into the environment.Space-Efficient: Their compact footprint allows for installation on ground-level concrete pads in confined spaces like greenways or parking lots.

Reliability for Underground Systems: Specifically designed to interface with underground secondary distribution cables, providing a clean and reliable power supply with reduced outage rates from above-ground threats like weather.Selection Considerations: Voltage rating, load capacity, and specific environmental conditions (e.g., corrosion resistance for coastal areas).

2. Pole-Mounted Transformers: The Workhorses of Overhead Distribution

Ideal For: Overhead power lines in rural electrification projects, agricultural areas, roadside distribution, and small communities.Key Characteristics & Advantages:

Elevated Installation: Mounted on utility poles, protecting them from flooding, wildlife interference, and vandalism, while saving ground space.

Cost-Effectiveness: Generally offer a lower total installed cost for overhead networks compared to underground alternatives.

Ease of Maintenance: Utilities can easily access and service them without disrupting ground-level activities.

Selection Considerations: Primarily for overhead systems. Key factors include kVA rating, phase (single or three-phase), and the climatic conditions of the region (e.g., resistance to lightning surges).

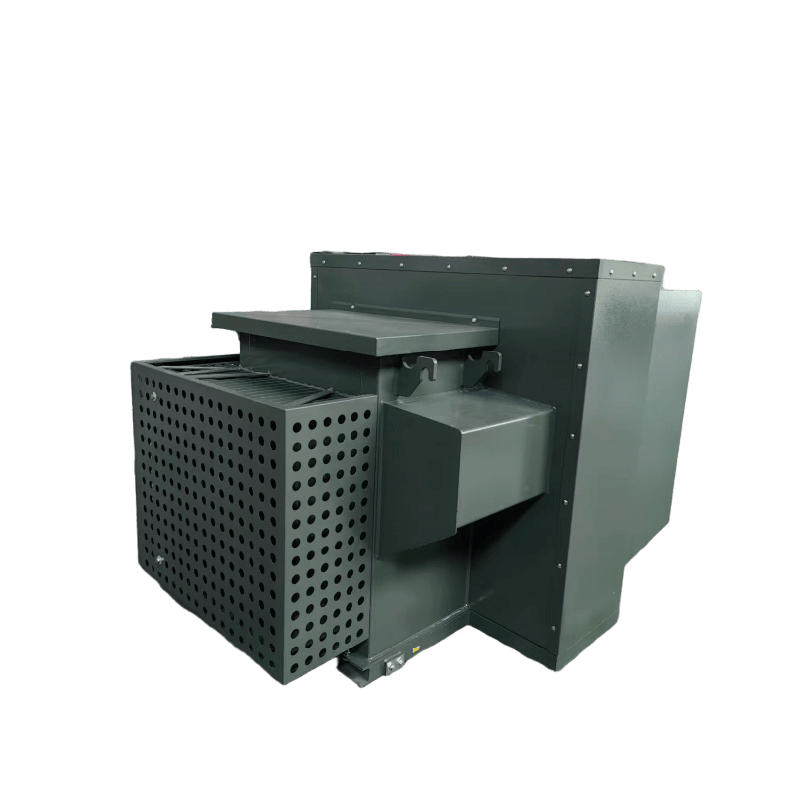

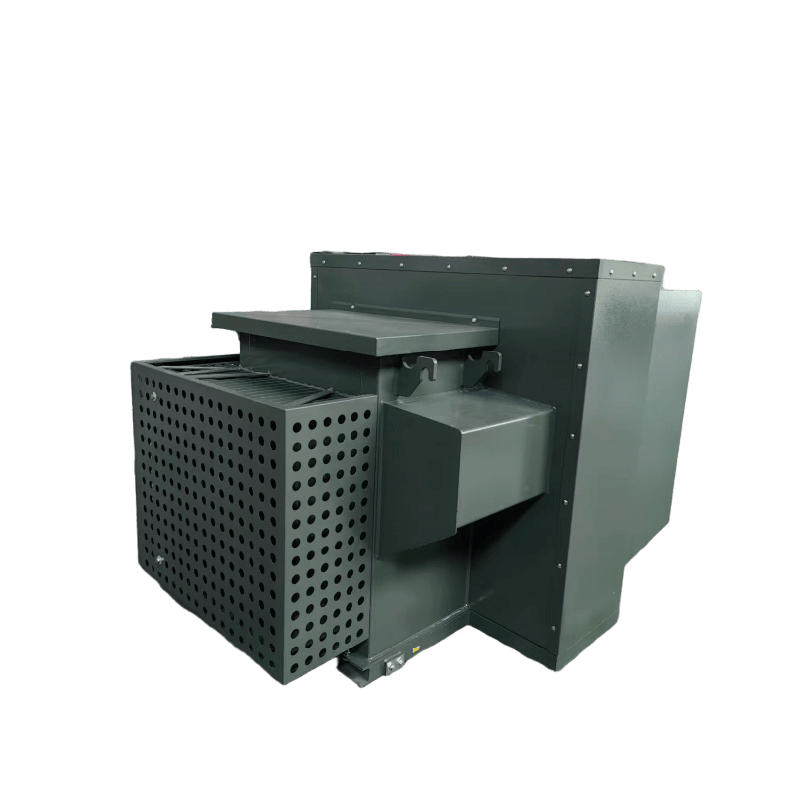

3. Mining Transformers: Engineered for Extreme Duty

Ideal For: Surface and underground mining operations, quarrying, tunneling, and other heavy industrial sites with harsh environments.Key Characteristics & Advantages:

Ruggedized Construction: Built with reinforced tanks and components to withstand vibration, mechanical impact, and extreme temperatures.

Enhanced Safety Certifications: Often designed to meet stringent safety standards (like MSHA or ATEX/IECEx) for operation in potentially explosive or flammable atmospheres. Features include flame-retardant fluids and sealed enclosures to keep out dust and moisture.

Maximum Reliability: Engineered for uninterrupted operation under constant stress, as downtime in mining applications is exceptionally costly.

Selection Considerations: Safety certification requirements (e.g., flameproof/explosion-proof), voltage class, and ability to handle heavy starting loads from industrial equipment.

4. Substation Power Transformers: The Grid's High-Voltage Hubs

Ideal For: Generation plants, transmission substations, large industrial plants, and major distribution substations.Key Characteristics & Advantages:

High Power Capacity: Designed to handle extremely high voltages and power levels (often ranging into the hundreds of MVA) for bulk power transmission and primary distribution.

Ultra-High Efficiency: Optimized to minimize energy losses when transforming voltage levels across the grid, which is critical for utility-scale economics.

Grid Stability: Equipped with tap changers and monitoring systems to help regulate voltage and maintain the stability of the entire power network.

Selection Considerations: Power rating (MVA), voltage ratio, impedance, cooling method (ONAN, ONAF, OFAF), and loss evaluation criteria.

Summary Comparison Table

| | | | |

|---|

| Urban / Suburban Distribution | Rural / Overhead Distribution | Heavy Industry (Mining, etc.) | Utility Transmission & Distribution |

| | | | |

| Public Safety & Aesthetics | Cost-Effectiveness & Accessibility | Ruggedness & Explosion Safety | Efficiency & Grid Reliability |

| | | Severe (Dust, Moisture, Vibration) | Controlled / Utility-Grade |

Conclusion: The Right Choice Powers Success

The optimal transformer choice is not a one-size-fits-all decision but a strategic one based on environment, safety regulations, load requirements, and total cost of ownership. Understanding these key differences is the first step toward specifying a solution that ensures safety, reliability, and efficiency for years to come.

At Qinghao, we don't just manufacture transformers—we provide engineered solutions. Our experts have deep experience across all these categories, helping our clients navigate these critical decisions for their specific projects.Ready to Specify the Perfect Transformer for Your Project?

Don't leave this critical decision to chance. Contact our engineering team today for a free, no-obligation consultation. We'll help you analyze your requirements and select the optimal transformer for performance, safety, and value.Schedule Your Free Consultation Now!